Production Work Order

The Work Order system is fully integrated with MRP and the Shop Floor Control system to provide real-time information on your jobs. The module can offer advanced functionality specifically designed to tackle the repetitive, job-based process of manufacturing operations.

Some of the system’s features:

- Make to order; generate work orders direct from Sales Orders

- MRP; Mass work order release, generate work orders based on MRP planning

- Batch size/lot control for process manufacturing

- Lot control assigned at job start or at job receiving

- Material substitutions are possible within work order or during work order reporting

- Work order schedules based on routings/capacity

- Gang work orders to combine common operations/materials from multiple work orders in progress to simplify reporting

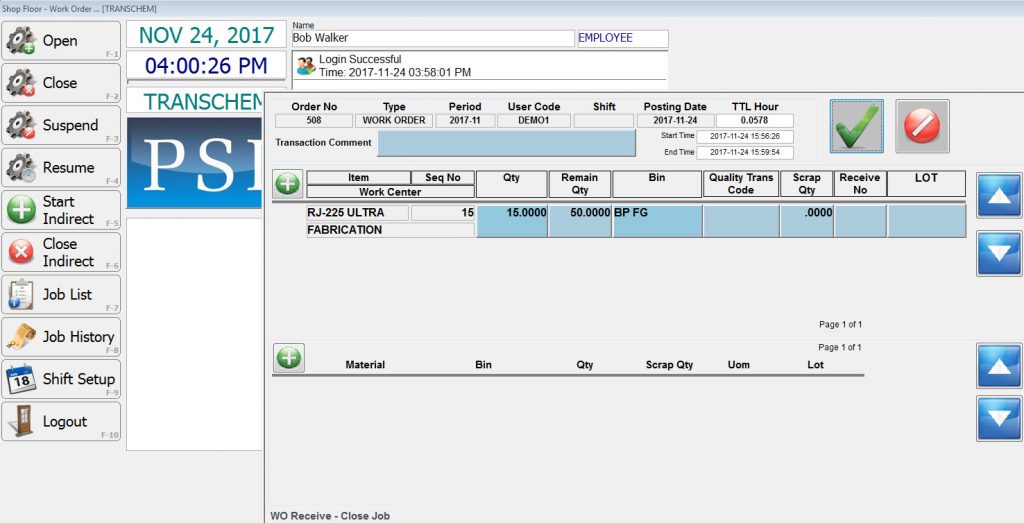

Shop Floor Control

The Shop Floor Control module empowers you with complete control over your production activity. You can track work orders from inception to completion, tracking all costs accrued at each production step along the way.

Some of the other features include:

- Multiple reporting options

- Real time shop floor reporting

- Indirect vs Direct labour tracking

- Suspend/resume jobs

- Work on multiple jobs

- Crew functionality

- In-process scrap reporting

- Scannable user badges

- Time sheet simplified reporting

- Online drawing

- Online, in-process drawing and work instructions

- Routing data to provide efficiency targets

- Material picking information

- Step-by-step tracking with time and user stamps

- Support for most current data collection devices

Inventory Management

Inventory planning is a critical part of the supply chain for manufacturing and distribution businesses. Holding inventory at just-in-time levels to meet your production demand can be challenging.

LeanEra can help. A real-time inventory system, it means that all transactions that you process will update instantly.

Some of the features on offer:

- Inventory planning tools;

- Shortage inquiry

- Date shortage

- Inventory plan

- MRP

- Sales forecast

- Item parameters including safety stock, days of supply, min/max/multiples

- Fast MRP calculation

- MRP-driven mass order release

- Perpetual Lot Information records including chain of custody

- Inventory management tools

- Year-end physical with audit reports

- Cycle counts

- Inventory activity report

- Transaction summary inquiry; audit trail for all inventory transactions

- Item cost inquiry