LeanEra is a feature-rich suite of applications for product engineering, construction, formula design, and quality management. The software modules work independently yet interact integrally to provide full visibility into your production. This helps you better manage material and capacity.

Item Master

The Item Master module contains information that is central to many other modules. The data from this module will be used by LeanEra™ for:

- Item Grouping and Categorization

- Item categories and grouping help with sales analysis, cost rollup, and reporting.

- Product Subgroup – subgrouping enables seamless categorization across Sales, Production, Planning, and Accounting functions. It makes finding the right item simple.

- Item Class – secondary grouping for sales analysis

- Inventory Class – for inventory planning

- Item Type – for different item functionality i.e.: Expense Items vs. Finished Goods items

- Phantom Item

- MRP parameters

- Work Order and Purchase Order min/max/multiple release parameters

- Item Serialization and Lot Control

- Costing – multiple costing methods are available, including Standard, Actual, Current, Lot, and Custom.

- Smart part number creation – item codes are generated automatically using item attributes. Each character/digit in the item code represents a unique meaning. Part numbers are in unique sequence and format, which makes them easy to search for.

- Multiple units-of-measure (UoM) and item specific UoM conversions are available for purchasing, inventory, and selling.

Bill of Material

The Bill of Material system is an easy and effective way to create and maintain some of your most critical documentation. It offers:

- Tree-view system that provides visual images

- Multi-level BOM

- BOM explosion/implosion views

- Mass update and mass delete functions

- Effective materials date phase in/out

- Child work order functionality

Routing

The Routing system gives you all the information you need about the manufacturing process of a specific item. This module, along with the Bill of Material module, provides a complete hierarchy of manufacturing information on which much of costing and scheduling is based.

- Assign material to backflush at specific operation steps

- Primary and secondary routings

- Work instructions that support ISO/QS/TS systems

- In-process drawing attachments for each operational step

- Alternate work centers

- Standard labour rates

- Variable time units

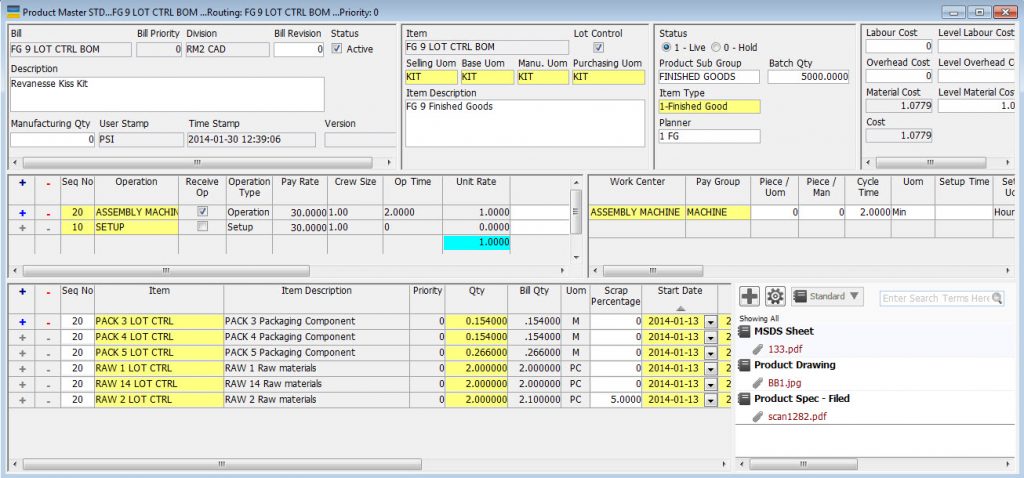

Product Master

Product Master brings efficiency to the process of creating standard products. This module is a consolidated view of Item Master, Bill of Material, and Routing in a single space, allowing you to copy entire product structures to create new ones. Under security/role control, user can view and modify your BoM, routing, and work center.

Product images and technical documents or drawings can be attached to the product master and configured to print along with corresponding work orders.

Formula Master

This module helps chemical manufacturers formulate their products more efficiently. Similar to the product master, this is a consolidation of the Batch Table, Bill of Material, and Item Master and is geared to meet the specific needs of producers of batch-processed products. Some of the main features of this module are that it:

- Uses materials percentage calculation as well as allows fixed quantity

- Allows materials with different UoM

- Offers batch sizing control and complies with standard batch parameters.

- Provides version control and version history

- Supports the attachment of engineering and processing notes, documents, and drawings

- Keeps documentation for SRED claims